Delphi Automotive was my dream job coming out of college and I landed a spot on the test engineering team. My first project was to manage $2M worth of Delco’s vehicle calibration equipment called the Modular Development System (MDS).

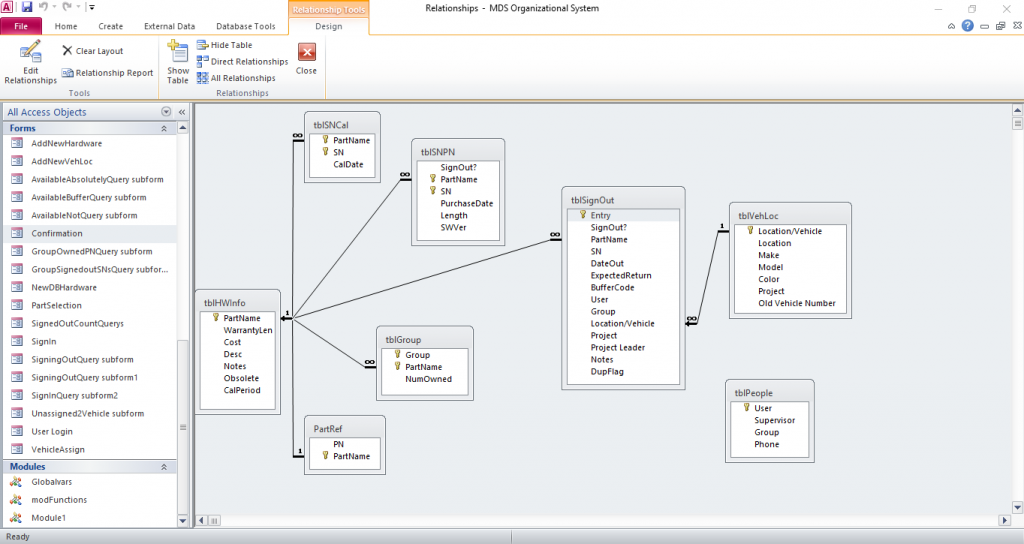

I met with each calibration group and collected inventory of their equipment. Then, I used MS Access to create the MDS Organizational System (MDSOS). This was a play on words, too, incorporating “SOS” in the title because the calibration groups were at odds with each other when it came to sharing equipment and really needed help.

They refused to share because they had no established way of communicating project needs and deadlines with each other and hence didn’t trust that they’d get their shared equipment back in time for their own project. My MDSOS coordinated exactly these elements and saved an estimated $1.2M over the years it was used due to the sharing (versus buying more equipment).

In MS Access, I built a GUI that any calibration team could access from their own computer to make a request for a vehicle to be built and MDS equipment (among other systems) to be installed. It saved their request to my public server drive (not so easy in 1999!) and notified me that a build had been requested.

On the complimentary MS Access database, the build requests were received and inventory maintained. In it, a build request automatically produced a build sheet for the build team and a table entry for me to use in determining whose equipment could be shared to cover the build’s needs. Below are animations and screenshots of the system, including some sample VB code and SQL.

MDSOS Build Request Interface (animated gif):

MDSOS Component Scheduling:

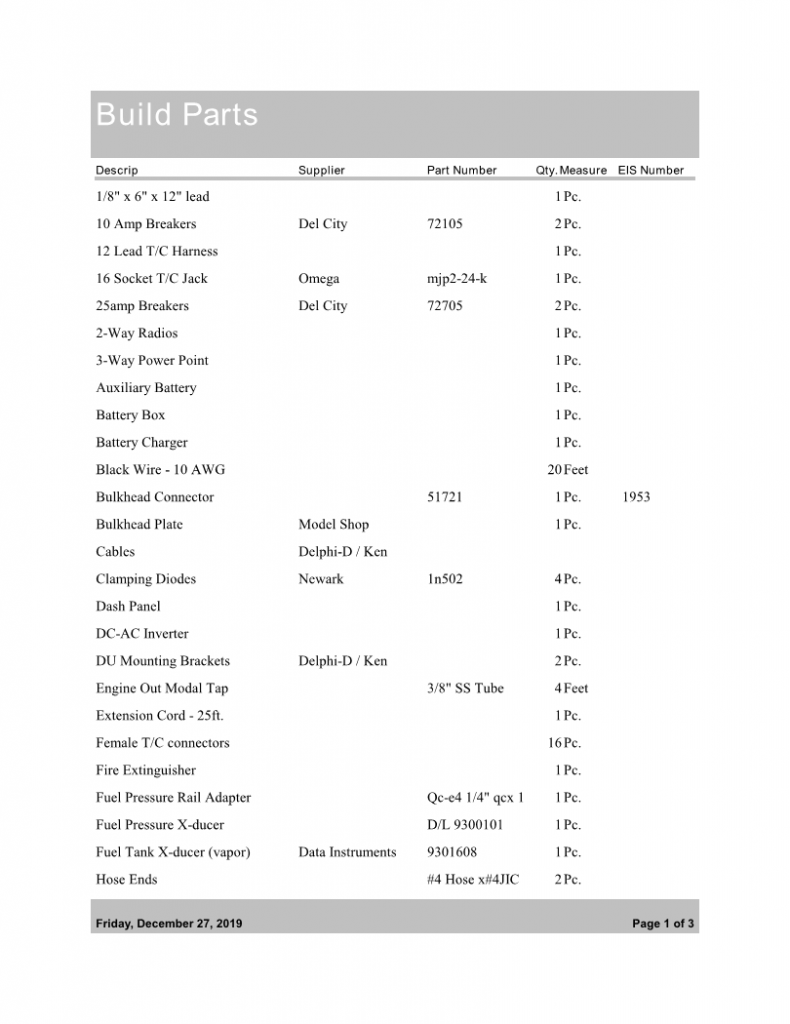

Sample Build Sheet (sent to vehicle build team):

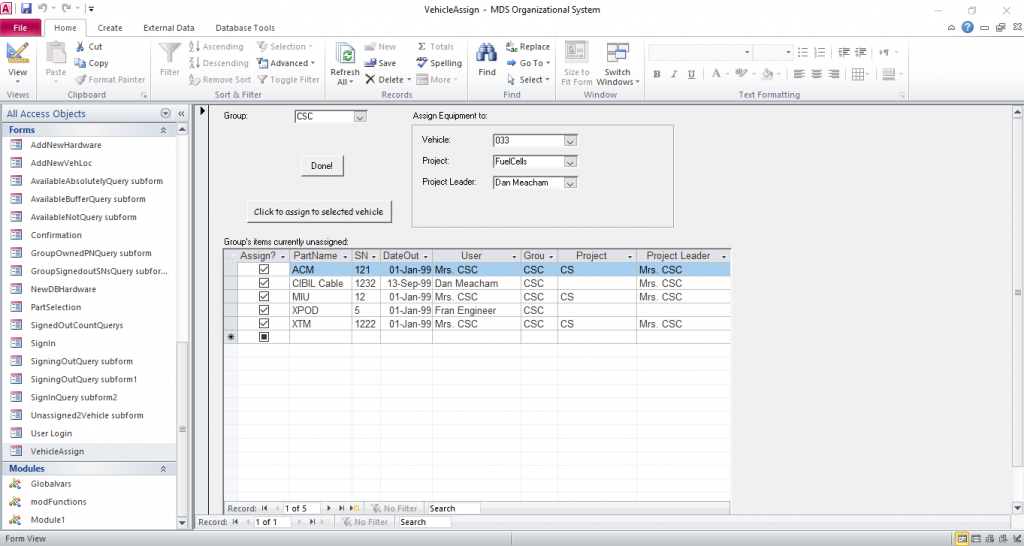

MDSOS Assigning Parts to Vehicles for Tracking

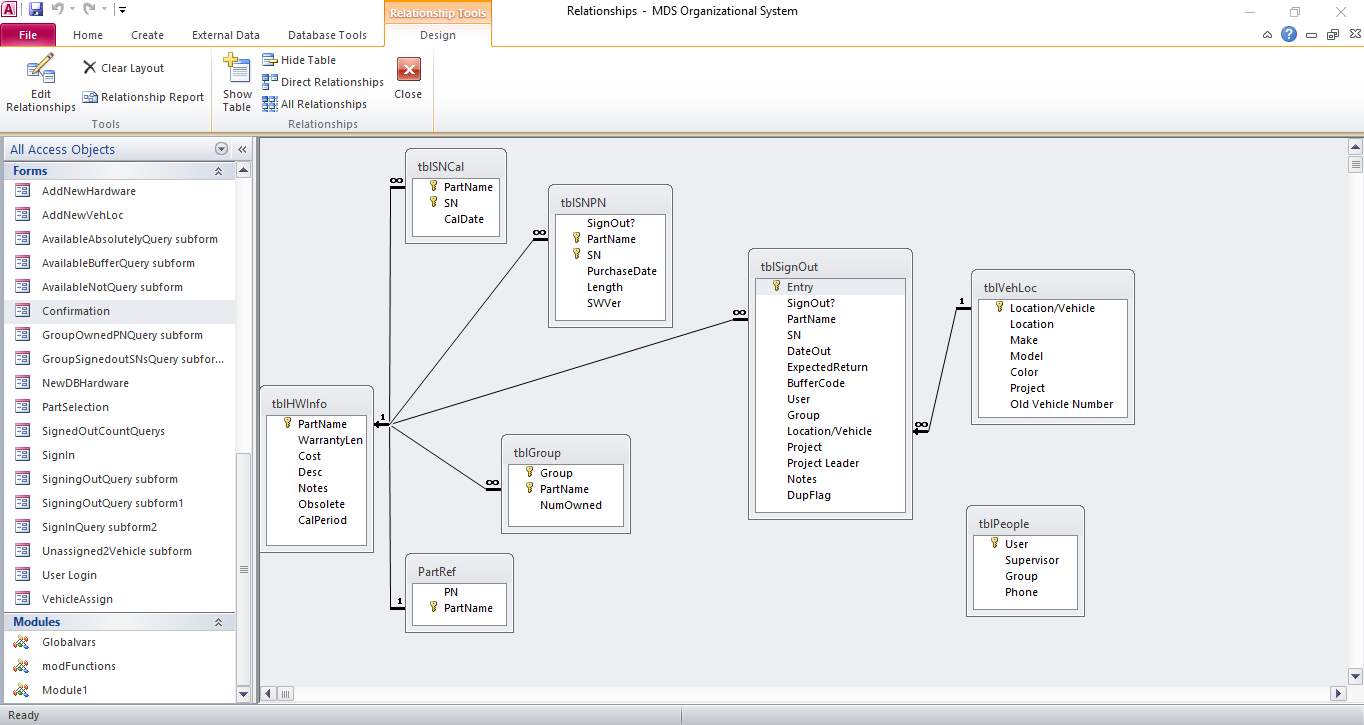

MDSOS Backend – Table Relationships

MDSOS Backend – Visual Basic Code and SQL